T: +86-13302905061

E: sales@dongli2006.com

E: sales@dongli2006.com

Building 101, No.5 Rixing Street, Pingdong Community, Pingdi Street, Longgang District, Shenzhen, Guangdong, China.

Views: 0 Author: Site Editor Publish Time: 2025-06-11 Origin: Site

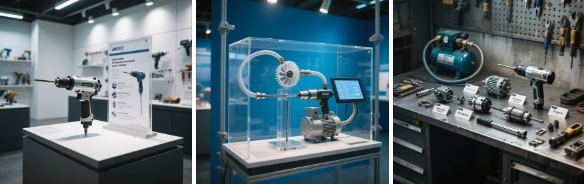

In the world of industrial tools, the pneumatic screwdriver stands out as a powerful and efficient solution for driving screws with precision and speed. Dongli Industrial Equipment (Shenzhen) Co., Ltd., established in December 2006, specializes in the development, production, and sales of industrial-grade pneumatic tools, including the highly regarded pneumatic screwdriver. This article explores the functionality, benefits, applications, and latest trends in pneumatic screwdrivers, with a focus on the products offered by Dongli Industrial Equipment.

A pneumatic screwdriver, also known as an air screwdriver, is a powerful tool that uses compressed air to drive screws into various materials. Unlike manual or electric screwdrivers, pneumatic screwdrivers offer several advantages, including high torque, consistent performance, and reduced user fatigue. These tools are widely used in industrial settings where speed, precision, and reliability are crucial.

The Pneumatic Screwdriver works based on the energy conversion of compressed air, and the pneumatic system drives the internal mechanical structure to achieve efficient fastening.This energy is then transferred to the screwdriver’s shaft, providing the necessary torque to drive screws efficiently. The speed and torque of a pneumatic screwdriver can be easily adjusted using a control valve, allowing users to match the tool’s performance to the specific task at hand.

Air Compressor: The source of compressed air that powers the tool.

Air Hose: Connects the air compressor to the screwdriver.

Control Valve: Allows users to adjust the speed and torque.

Bit: The interchangeable tip that matches the head of the screw.

Pneumatic screwdrivers offer several advantages over manual and electric screwdrivers, making them a preferred choice in many industrial applications.

Pneumatic screwdrivers deliver high levels of torque, making them ideal for driving large or stubborn screws. This high torque capability ensures that screws are driven securely and efficiently, reducing the risk of stripping or damage to the screw head.

Unlike electric screwdrivers, which can experience power fluctuations, pneumatic screwdrivers provide consistent performance. The use of compressed air ensures a steady supply of power, resulting in uniform screw driving every time. This consistency is crucial in industrial settings where precision and reliability are paramount.

The high power-to-weight ratio of pneumatic screwdrivers means that users can work for extended periods without experiencing significant fatigue. The tools are lightweight and easy to handle, making them ideal for repetitive tasks.

Pneumatic screwdrivers are built to withstand the rigors of industrial use. Their robust construction and simple design mean they are less prone to mechanical failure compared to electric screwdrivers. With proper maintenance, pneumatic screwdrivers can last for many years, providing a reliable and cost-effective solution.

Pneumatic tools, including screwdrivers, are generally considered safer than their electric counterparts. They do not produce sparks, making them suitable for use in environments where flammable materials are present. Additionally, the absence of electrical components reduces the risk of electric shock.

Pneumatic screwdrivers are versatile tools used in a wide range of industries and applications. Their high torque, consistent performance, and durability make them ideal for tasks that require precision and reliability.

In the automotive industry, pneumatic screwdrivers are used extensively for both assembly and repair tasks. They are particularly useful for driving large screws and bolts in engine components, transmissions, and body panels. The high torque and consistent performance ensure that screws are driven securely and accurately, reducing the risk of damage to delicate components.

Pneumatic screwdrivers are also widely used in the electronics industry for assembling and repairing delicate components. Their precise control and consistent performance make them ideal for tasks that require high accuracy and reliability. The reduced risk of electrical interference also makes them safer to use in sensitive electronic environments.

In construction, pneumatic screwdrivers are used for driving screws into various materials, including wood, metal, and plastic. Their high torque and power make them ideal for tasks that require a strong and secure fastening. Pneumatic screwdrivers are particularly useful in situations where power tools are not feasible, such as in remote locations or during power outages.

Pneumatic screwdrivers are commonly used in furniture assembly, where precision and speed are crucial. They ensure that screws are driven securely and accurately, reducing the risk of damage to the furniture. The high torque and consistent performance also make them ideal for repetitive tasks, such as assembling large pieces of furniture.

Pneumatic screwdrivers are invaluable for general maintenance tasks, including fixing and repairing items around the home or workplace. Their versatility and reliability make them suitable for a wide range of applications, from securing loose screws in doors and windows to repairing electronic devices.

Dongli Industrial Equipment (Shenzhen) Co., Ltd. offers a range of high-quality pneumatic screwdrivers designed to meet the demands of industrial applications. Their pneumatic screwdrivers are known for their durability, precision, and reliability. Let’s take a closer look at some of the key features and benefits of Dongli’s pneumatic screwdrivers.

High-Quality Materials: Dongli’s pneumatic screwdrivers are made from high-grade steel, ensuring durability and resistance to wear and tear.

Ergonomic Design: The handles are designed for comfort, reducing hand fatigue during extended use.

Precision Tips: The tips are precisely machined to fit the screws perfectly, reducing the risk of stripping.

Variable Speed Control: Allows users to adjust the speed and torque according to the task at hand.

High Torque and Power: Ensures screws are driven securely and efficiently, reducing the risk of stripping or damage.

Consistent Performance: Provides uniform screw driving every time, ensuring precision and reliability.

Reduced User Fatigue: Lightweight and easy to handle, making them ideal for repetitive tasks.

Durability and Longevity: Built to withstand industrial use, ensuring long-lasting performance.

Safety: Suitable for use in environments where flammable materials are present, reducing the risk of electrical interference.

To better understand the value of pneumatic screwdrivers, it’s useful to compare them with other tools in the market. Below is a table that highlights the key differences between pneumatic screwdrivers and other common tools used for driving screws.

| Feature/Tool | Pneumatic Screwdriver | Electric Screwdriver | Manual Screwdriver |

|---|---|---|---|

| Power Source | Pneumatic (Air Compressor) | Electric (Corded/Cordless) | Manual |

| Speed Control | Variable Speed | Variable Speed | Fixed Speed |

| Torque | High | Medium | Low |

| Effort Required | Low | Low | High |

| Portability | Medium (Air Hose) | Medium (Cordless) | High |

| Versatility | High | High | Low |

| Price | High | Medium | Low |

Electric screwdrivers offer several advantages over manual screwdrivers, including reduced physical effort and increased speed. However, pneumatic screwdrivers have several key advantages over electric screwdrivers. Pneumatic screwdrivers deliver higher torque and consistent performance, making them ideal for tasks that require precision and reliability. They are also generally more durable and less prone to mechanical failure compared to electric screwdrivers.

Manual screwdrivers are simple and reliable tools that do not require a power source. However, they require significant physical effort and are slower compared to pneumatic screwdrivers. Pneumatic screwdrivers offer high torque and speed, making them ideal for tasks that require precision and efficiency. They are also more versatile and can be used in a wider range of applications.

The market for pneumatic screwdrivers is constantly evolving, with new trends and innovations emerging regularly. These advancements not only enhance the functionality and usability of pneumatic screwdrivers but also align with modern demands for efficiency, comfort, and sustainability. Some of the latest trends include:

Manufacturers are placing greater emphasis on ergonomic design to reduce user fatigue and improve comfort. This includes the use of softer, more comfortable materials for handles, often incorporating rubberized grips that provide better traction and reduce slippage. Additionally, features such as anti-vibration technology are being integrated to minimize the transmission of force to the user’s hand, making prolonged use more comfortable and less strenuous.

Modern pneumatic screwdrivers are designed with precision and durability in mind. High-grade steel is commonly used for the shafts and tips, ensuring that the tools can withstand repeated use without wear or deformation. Precision machining techniques are employed to create tips that fit screws perfectly, reducing the risk of stripping and ensuring a secure fit every time. These advancements make pneumatic screwdrivers more reliable and longer-lasting, providing better value for money.

While pneumatic screwdrivers are inherently powerful tools, some manufacturers are beginning to integrate smart features. For example, some advanced models may include built-in torque indicators that provide feedback on the amount of force being applied. This can be particularly useful in applications where precise torque control is required, such as in automotive or electronics repair. Additionally, some pneumatic screwdrivers are designed with compatibility in mind, allowing them to be used with various attachments or extensions for added versatility.

To cater to the diverse needs of users, many manufacturers now offer customization options for their pneumatic screwdrivers. This can include adjustable handle sizes, interchangeable handle materials, and even personalized engravings. Customization not only enhances the user experience but also allows professionals to tailor their tools to specific tasks or preferences, further improving efficiency and comfort.

In response to growing environmental concerns, there is a significant focus on sustainability in the manufacturing of pneumatic screwdrivers. Companies are increasingly using eco-friendly materials, such as recycled plastics and sustainably sourced metals, to produce their tools. Additionally, manufacturers are adopting sustainable production practices to reduce waste, energy consumption, and their overall carbon footprint. By choosing pneumatic screwdrivers made from eco-friendly materials, consumers can contribute to a more sustainable future without compromising on quality or performance.

Pneumatic screwdrivers offer several key advantages over electric screwdrivers:

High Torque and Power: Ensures screws are driven securely and efficiently, reducing the risk of stripping or damage.

Consistent Performance: Provides uniform screw driving every time, ensuring precision and reliability.

Reduced User Fatigue: Lightweight and easy to handle, making them ideal for repetitive tasks.

Durability and Longevity: Built to withstand industrial use, ensuring long-lasting performance.

Safety: Suitable for use in environments where flammable materials are present, reducing the risk of electrical interference.

When selecting a pneumatic screwdriver, consider factors such as the type of screw you will be working with, the size of the screw, and the material you are working with. Additionally, look for features such as ergonomic handles, variable speed control, and precision tips for added convenience and precision.

Yes, pneumatic screwdrivers are well-suited for sensitive applications such as electronics assembly. Their precision and control make them ideal for tasks that require careful handling of delicate components. Additionally, the reduced risk of electrical interference makes them safer to use in sensitive electronic environments.

Modern pneumatic screwdrivers feature several innovations, including ergonomic handles, precision tips, and variable speed control. Some advanced models also include smart features such as built-in torque indicators and compatibility with various attachments or extensions. Additionally, manufacturers are focusing on environmental sustainability by using eco-friendly materials and adopting sustainable production practices.

Pneumatic screwdrivers and manual screwdrivers both offer high precision and versatility. However, pneumatic screwdrivers are more powerful and efficient, making them ideal for tasks that require high torque and consistent performance. Manual screwdrivers are simpler and more portable but require more physical effort and are slower compared to pneumatic screwdrivers.

Pneumatic screwdrivers have proven to be highly effective tools in a variety of industries. With their combination of high torque, consistent performance, and durability, they offer significant advantages over manual and electric screwdrivers. Dongli Industrial Equipment (Shenzhen) Co., Ltd. has established itself as a leader in the production of high-quality pneumatic screwdrivers, offering tools that meet the demands of industrial applications while also being user-friendly and affordable.

As technology continues to advance, we can expect to see even more innovations in the field of pneumatic screwdrivers. From ergonomic designs to smart tool integration and environmental sustainability, the future looks bright for these powerful and versatile tools.

In conclusion, pneumatic screwdrivers are indeed very good. They offer a range of benefits that make them indispensable in both professional and DIY settings. Whether you’re assembling a piece of furniture, repairing a vehicle, or maintaining electronic equipment, a pneumatic screwdriver can significantly enhance your productivity and precision.